Few pieces of heavy machinery are more versatile than an excavator, maybe with the exception of a skid steer. Industries such as metal recycling, construction, forestry, pipeline installation and maintenance, and railroads all use excavators habitually. While the most common use for excavators is for the purpose of digging and trenching, there are several attachments available that can make an excavator much more adaptable. Additionally, by having multifaceted attachments, your company can accept more jobs, earn more revenue, hire more individuals, and grow the company as a whole. If you’d like to learn about the different types of excavator attachments, our experts have you covered. Read on to learn more.

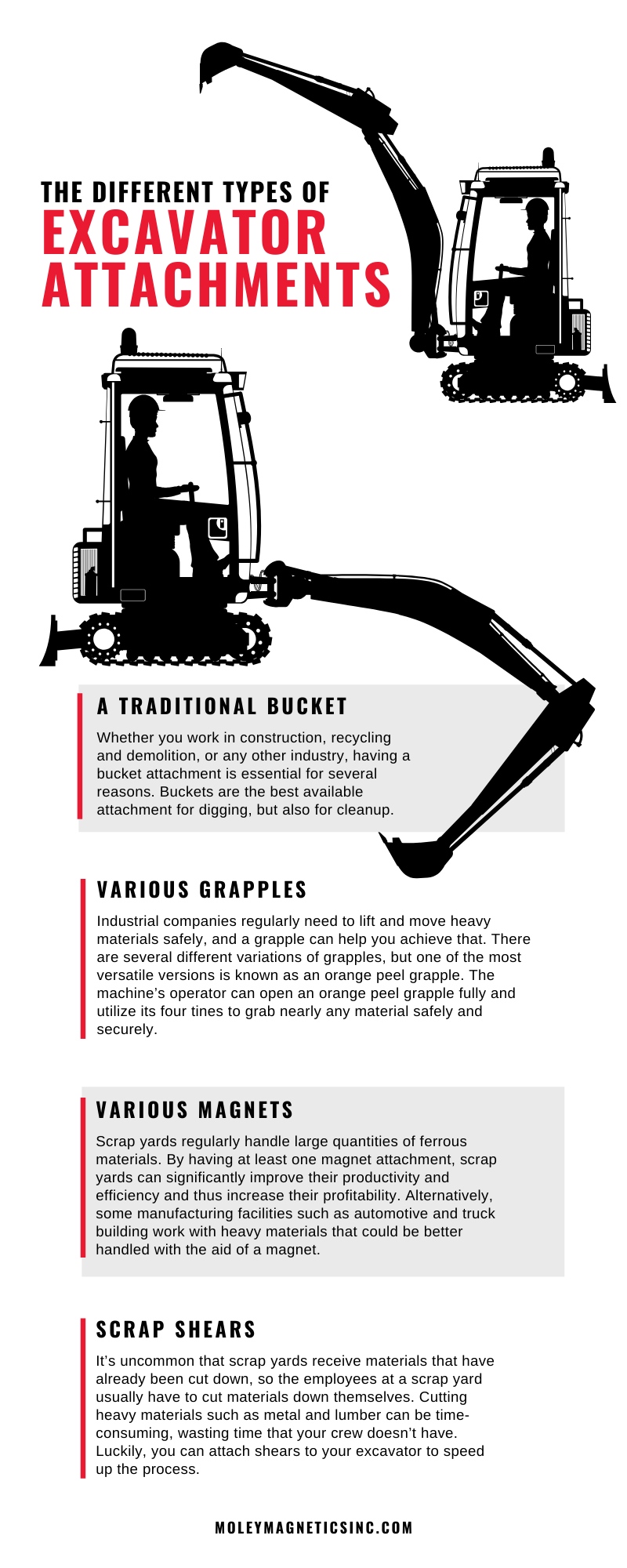

A traditional bucket

When a person envisions an excavator, they almost certainly picture a bucket attachment. Whether you work in construction, recycling and demolition, or any other industry, having a bucket attachment is essential for several reasons. First and foremost, buckets are the best available attachment for digging, but also for cleanup. In addition, you can use a bucket for general lifting needs. You should, however, be careful when lifting items because items aren’t necessarily secure in a bucket as they would be in a grapple. However, if your company owns an excavator, chances are you also own a bucket. That said, let’s get into the other attachments that you should have in your arsenal.

Various grapples

Industrial companies regularly need to lift and move heavy materials safely, and a grapple can help you achieve that. There are several different variations of grapples, but one of the most versatile versions is known as an orange peel grapple. When closed, the orange peel grapple looks like it could hold an orange in the center. On the other hand, the machine’s operator can open an orange peel grapple fully and utilize its four tines to grab nearly any material safely and securely.

Our orange peel grapples come with several features that make them superior to others. First, the attachment is made with certified steel from HARDOX and WELDOX. Additionally, the hinges and rods are both made with hardened steel, and the blade tips are made of a type of steel that reinforces durability. To ensure the grapple is ideal for your specific application, we offer three tine configurations: Closed, semi-closed, and straight. Each configuration has its own advantages, if you’re handling smaller materials that could fall out of the grapple, you’d likely benefit from the extra plates of a closed tine. On the other hand, if you merely handle large items such as lumber, straight tines would best fit your needs. Of course, if you handle a bit of everything, a semi-closed configuration would work best.

Various magnets

Industrial magnets are an essential excavator attachment in several industries, but the most notably used in manufacturing and scrap yards for a couple of primary reasons. First, scrap yards regularly handle large quantities of ferrous materials. By having at least one magnet attachment, scrap yards can significantly improve their productivity and efficiency and thus increase their profitability. Alternatively, some manufacturing facilities such as automotive and truck building work with heavy materials that could be better handled with the aid of a magnet. Depending on your company’s needs, you may find the most value in an electromagnet. An electromagnet is a magnet that you can turn on and off that requires an external power source.

On the other hand, if you’re in an industry like metal recycling that uses magnets every day, a permanent magnet would be sufficient for your uses. Unlike the electromagnet, you can’t turn a permanent magnet on and off, as the magnet is always live. In other words, to determine which magnet is best for your company, you need to analyze your application and how frequently you plan to use the magnet.

Scrap shears

It’s uncommon that scrap yards receive materials that have already been cut down, so the employees at a scrap yard usually have to cut materials down themselves. Cutting heavy materials such as metal and lumber can be time-consuming, wasting time tThe Different Types of Excavator Attachmentshat your crew doesn’t have. Luckily, you can attach shears to your excavator to speed up the process.

Our industry experience means we know that you’re trying to boost efficiency anywhere possible. In fact, our shears boost cycle time by up to 50% when compared to a hydraulic sThe Different Types of Excavator Attachmentsystem. Additionally, our shears have several features that support durability, reliability, and usability. For instance, we know how much time you can waste by repositioning your machine. To save your team some time, our shears feature a 360-degree rotation that allows you to use the shears regardless of the machine’s position. For the best possible cut, our shears feature an offset jaw apex which allows for added pressure and an overall better result. Additionally, our shears help you avoid unexpected downtime from jams with our dual guided blades. Finally, we provide dual slide pucks on our shears to increase the blade’s longevity by reducing jaw deflection.

As you likely noticed, many of the different types of excavator attachments are designed with a particular application in mind. That said, by using attachments that are specific to your application, you’re going to see increases in productivity and efficiency which should help you increase your profits. However, your operations can only go as far as your attachments allow. If you’re using the cheapest attachment you could find, your attachments are never going to last, and you’ll spend more money on repairs or replacements in the long run. We know your team needs equipment that’s both durable and reliable, and that’s why we only use top-quality materials for all our products.

If you’re looking for high-quality attachments or electric motors, Moley Magnetics has you covered. On the other hand, you might have existing attachments and you might need a repair service. We can help you in that aspect as well. Moley Magnetics is a family-owned company that began as a motor repair shop, and while we haven’t lost touch of our roots, we currently offer more services than motor repair services, such as magnet, grapple, machine shop, and pump repair services. If you’re ready to take your excavators to the next level with high-quality attachments, or if you simply need a repair, reach out to us for a free quote today. Additionally, if you have any questions, don’t hesitate to ask. We’re always happy to help.