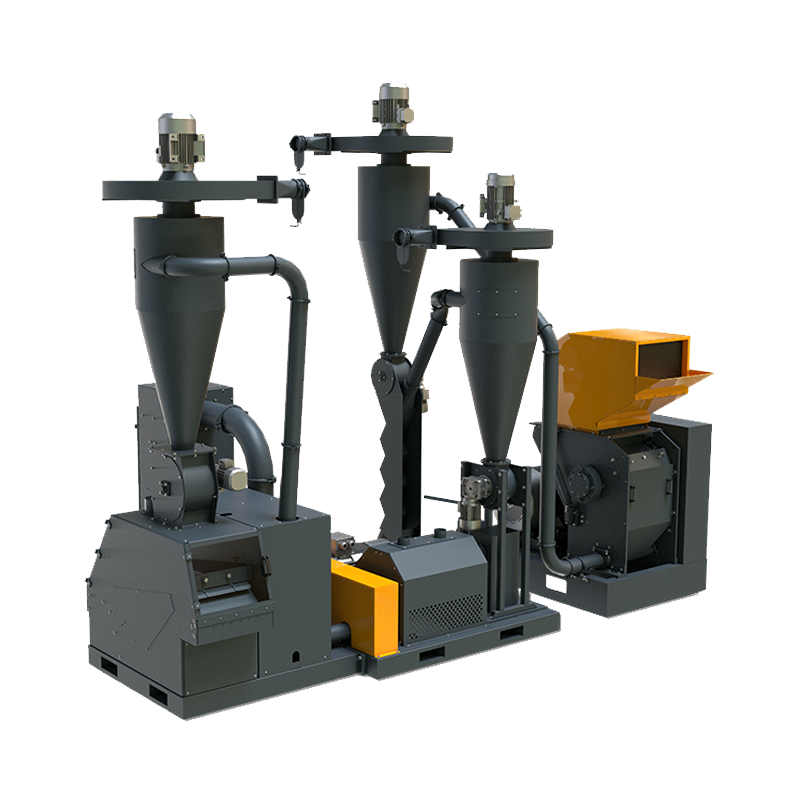

Product description

The granulators of the Multi-Flex Turbo Zig-Zag series are composed of three units: the grinding mill, the refining turbine, the densimetric table. The separate mill significantly increases the performance and flexibility of the granulator and reduces vibration phenomena by improving dissipation of the heat produced by grinding and facilitating routine maintenance. All Zig-Zag Multi-flex Turbo systems use a TURBO cell refiner and are available in four models with outputs starting at 350 kg/h. The presence of the TURBO cell refiner allows the processing of small diameter cables (telephone and data cables or capillaries) without the need of changing the processing grid or performing costly separation activities of the material to be treated. Multi-flex Turbo granulators are equipped with a zig-zag system for separating the rigid cable. Particularly robust and reliable, they allow the treatment of copper, aluminum and copper-aluminum radiators thanks to the robust grinding mills. The generously sized engines allow to overcome unexpected loads, guaranteeing uniform operations and low energy consumption. Multi-flex Turbo Zig-Zag granulators do not require forced cooling systems thanks to the generous sizing of all process components, transport pipes and material dosing cyclones.