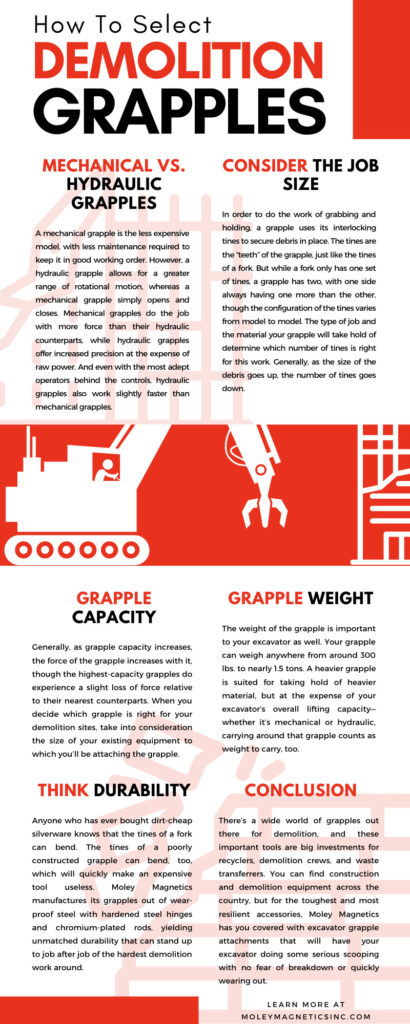

How To Select Demolition Grapples

Construction is an important, rewarding, and redeeming job. But demolition—that’s where the fun comes in. It’s hard to deny the sense of satisfaction that can come from tearing down an old building, watching it come down, and clearing the space out so that construction crews can start anew on that spot. But demolition isn’t all fun and games. There’s serious work to be done when it comes to taking down construction, and the serious work calls for serious tools.

Short of dynamite and the wrecking ball, the grapple is one of the most important attachments in most modern demolition tasks. This “iron claw” is a familiar sight anywhere buildings are being taken down. A demolition grapple does just what its name says: it grabs hold of scrap and debris and moves it out of the way, deftly handling a myriad of materials, from rebar to insulation. But despite the brute force inherent in demolition, one grapple does not fit all. There are many models of grapples for different types of jobs. Some will indiscriminately pick up as much material as they can. Others will concentrate on large objects and sift the small stuff out. In this guide to grapples, you can get a sense of the different approaches to handling demolition jobs and better determine how to select demolition grapples for your next upcoming tasks.

Mechanical vs. Hydraulic Grapples

An excavator grapple is generally powered in one of two ways: mechanically or hydraulically. Each comes with its benefits and drawbacks to consider in selecting a grapple. A mechanical grapple is the less expensive model, with less maintenance required to keep it in good working order. However, a hydraulic grapple allows for a greater range of rotational motion, whereas a mechanical grapple simply opens and closes. Mechanical grapples do the job with more force than their hydraulic counterparts, while hydraulic grapples offer increased precision at the expense of raw power. And even with the most adept operators behind the controls, hydraulic grapples also work slightly faster than mechanical grapples, which can save valuable time and energy in the long run. Do they save enough time to justify the increased price and higher level of necessary upkeep? It’s certainly a question you’ll have to ask based on your demolition workload and the precision required in the lifting and relocation of onsite scrap.

Consider the Job Size

In order to do the work of grabbing and holding, a grapple uses its interlocking tines to secure debris in place. The tines are the “teeth” of the grapple, just like the tines of a fork. But while a fork only has one set of tines, a grapple has two, with one side always having one more than the other, though the configuration of the tines varies from model to model. The type of job and the material your grapple will take hold of determine which number of tines is right for this work. Generally, as the size of the debris goes up, the number of tines goes down. For instance, if you’re working with heavy steel rebar and need maximum force to grab and remove large scrap, you’ll want the lowest number of tines, a two-over-three configuration. This will allow smaller pieces to slip through the tines for you to come back for later after dealing with the most important parts. General demolition work with smaller pieces will usually call for three-over-four grapples, which still filters out smaller debris but is not quite as exclusive in what it will carry. For smaller bits and pieces, four-over-five and even five-over-six configurations are available.

Grapple Capacity

A demolition job doesn’t happen overnight, but Moley Magnetics offers demolition grapples that range in capacity from 0.5 cubic yards to 1.56 cubic yards for maximum debris capture. Generally, as grapple capacity increases, the force of the grapple increases with it, though the highest-capacity grapples do experience a slight loss of force relative to their nearest counterparts. When you decide which grapple is right for your demolition sites, take into consideration the size of your existing equipment to which you’ll be attaching the grapple. You want to make sure you have the excavator necessary to take on a high-capacity grapple.

Grapple Weight

The weight of the waste handling grapple is important to your excavator as well. Your grapple can weigh anywhere from around 300 lbs. to nearly 1.5 tons. A heavier grapple is suited for taking hold of heavier material, but at the expense of your excavator’s overall lifting capacity—whether it’s mechanical or hydraulic, carrying around that grapple counts as weight to carry, too. The heaviest of grapples may be necessary for the most daunting of tasks, but as with the aforementioned volume of the grapple, you’ll need to make sure your excavator is up to the job. You may have to take “smaller bites” of the job to get it done.

Think Durability

Anyone who has ever bought dirt-cheap silverware knows that the tines of a fork can bend. The tines of a poorly constructed grapple can bend, too, which will quickly make an expensive tool useless. Moley Magnetics manufactures its grapples out of wear-proof steel with hardened steel hinges and chromium-plated rods, yielding unmatched durability that can stand up to job after job of the hardest demolition work around. With these high-quality materials involved, you won’t have to worry about your grapple buckling under the pressure and leaving you unable to pick up the pieces.

Conclusion

There’s a wide world of grapples out there for demolition, and these important tools are big investments for recyclers, demolition crews, and waste transferrers. You can find construction and demolition equipment across the country, but for the toughest and most resilient accessories, Moley Magnetics has you covered with excavator grapple attachments that will have your excavator doing some serious scooping with no fear of breakdown or quickly wearing out. By taking issues of durability, capacity, and tine configuration into account, you can determine how to select a demolition grapple and proceed to the hard but gratifying work of tearing down and starting fresh.