How To Help Your Electric Motor Last Longer

Equipment is an investment, and like any investment, it’s one that you hope to maximize your return on. One piece of equipment that almost no facility can do without is some variety of electric motor. Whether it powers a CNC rig, a less sophisticated piece of heavy machinery, or anything in between, the industrial world needs motors.

Since electric motors are such a big part of a facility’s operations, it’s important they last for a while. A medium-horsepower DC motor should have a lifespan that falls somewhere between 5,000 and 10,000 hours. If you ran that motor for eight hours a day every workday, that would be somewhere between three and five years. Motors of different sizes and applications have different lifespans, of course. But the common thread uniting them is that you want to keep them running for as long as possible before it’s time for their retirement and replacement. Here’s how to help your electric motor last longer, no matter its role, and how to make the most of your investments.

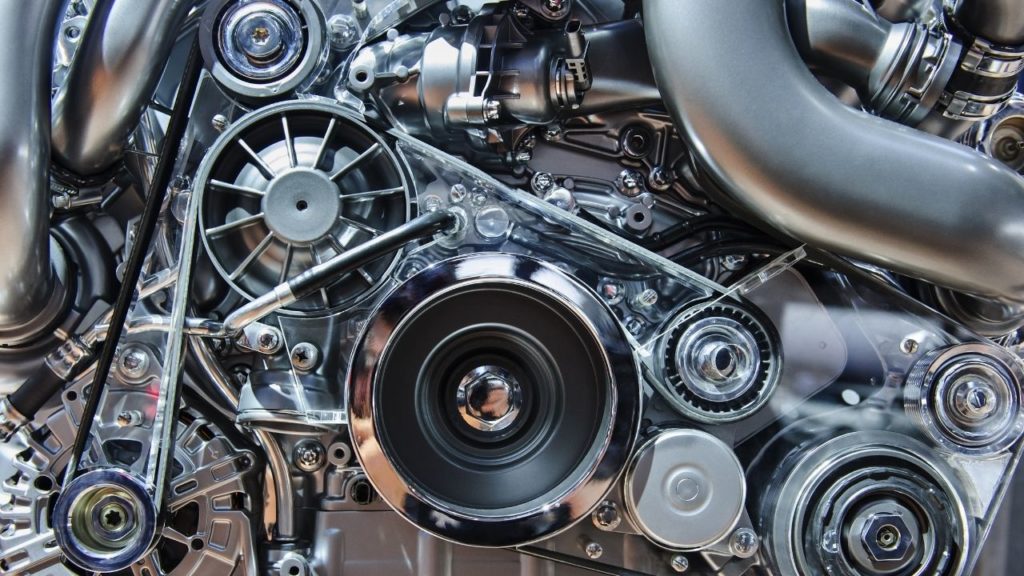

Prevent Overheating

Electric motors are resilient devices, but when the temperature rises to dangerous highs, you risk permanent and critical damage to your motor. In turn, this damage can have serious ramifications for the equipment your motor is powering. The longer a motor runs, the higher the likelihood of overheating. Shutting down electric motors intermittently may not be an option, but you may be able to protect against high operating temperatures. Integral to preventing overheating is checking the voltage that your motor is receiving. If your motor is taking excess voltage, that excess energy can turn into heat energy, which slowly but surely truncates the lifespan of a motor. Ascertain that your motor can cool itself off, largely by having unimpeded venting.

Keep It Clean

Cleaning the vents of a motor is important not just for overheating but to protect other sensitive operations as well. The dirt and dust of a motor’s surroundings can infiltrate the parts, which will shorten its lifespan. Fortunately, you don’t always need an experienced specialist to clean the vents of your motor and scrub away debris—it’s a task you can and should do yourself as part of a responsible everyday maintenance plan.

Stay Lubricated

Keeping your electric motor lubricated is just as important as keeping it clean. This reduces two factors that are most culpable in shortening motors’ lifespans: high heat and friction. It’s important not only to maintain proper lubrication on an electric motor but also to use the right lubricant. Avoid the temptation to use traditional automotive motor oil in a pinch—its detergent qualities can wear down sensitive bearings and reduce the useful life of your motor. Instead, stick to blends intended for electric motor use.

Practice Good Storage

Sometimes, it’s not what you do when your motor is running—it’s what you do when it’s not. There’s more than meets the eye to motor storage. When your motor goes off the floor for servicing or simply needs to move into storage for a while, it’s crucial to pack it properly. This means protecting it from heat, cold, dirt, moisture, and vibration. If you can keep your motor stowed away indoors in a dry and well-heated place, you’re almost to safe storage already. Extreme temperature shifts in either direction, but particularly one that sends the mercury downward, are hard on a motor’s bearings. Inconsistent temperatures also lead to condensation, and it doesn’t take a degree in engineering to realize that water that gets in an electric motor and stays there is going to shorten its lifespan—if not bring it to a premature close before removing it from storage.

Perhaps less evident but no less important to prolonging a motor’s useful life while out of commission is avoiding ambient vibration. Your motor may be tucked away, but it’s not asleep—what difference does it make if there’s noise around it? As it happens, the subtle shaking can permanently damage an electric motor—even one that’s been safely stored. Such vibrations can come from noisy surroundings, whether it’s the ambient sound of a factory floor, positioning on a rack that takes incidental contact, or even placement along an exterior wall that abuts a busy highway. Bumps, jostling, and mere vibration can all damage the bearings of a motor without your knowledge, leading to an unpleasant surprise when you try to bring a motor back into service. Store it as far away from any disturbances as you can.

Vibe Check

Continuing with how excessive vibration can get in the way of maximizing an electric motor’s lifespan, let’s talk about vibratory damage on a motor that’s in current use. Think about jogging and the importance of form. You can run with poor form and still achieve decent speeds with good stamina—for now. However, over time, poor form catches up with you and does damage to your soles and joints, putting your jogging days behind you before you’re ready to hang up the shoes. The same goes for the “form” of an electric motor. When a motor operates but does not do so smoothly, the vibration of parts that are slightly out of alignment wears down the motor, leading it to break down sooner than you’d like.

Detecting these defects isn’t always easy. You can picture in your head the rattling old motor of some old jalopy on its last legs, but a motor that’s experiencing too much vibration can be much more subtle than that. You should still keep your eyes peeled for smooth operations and take note of any rumbling that seems out of character, but to detect less perceptible but no less pernicious vibration within your motor, you may need some additional tools. Ultrasonic analysis can detect whether bearings are vibrating improperly and the extent to which they are—levels that may not be readily apparent to the naked eye. Harnessing ultrasound for maintenance purposes, whether by contracting with specialists or acquiring the technology yourself, can be an investment that protects your other investments.

Don’t Recycle That Motor Yet

Knowing how to help your electric motor last longer is useful information across a host of industries. Electric motors often power the hydraulic generators that keep our valuable metals in circulation by shredding, crushing, baling, and chopping them up on their way to being melted down for future use. Moley Magnetics specializes in equipment for this very important industry, and with these tips in mind, you’ll be shredding and chopping everything but the motor.