How To Check If an Electric Motor Is Going Bad

For centuries, we’ve seen tremendous innovation in industrial operations. Our ancestors worked diligently to find solutions to the sluggish processes they experienced, which ultimately led us to the development of motors and automation. Today, countless companies rely on electric motors to make their operations more efficient. While motors have certainly made significant improvements to the operations of businesses, companies also must maintain their motors to avoid downtime. In order to prevent future downtime and inefficiencies, you must know how to check if an electric motor is going bad. If you know how and what to look for in a motor, you can take action early and prevent your motor from going down and potentially getting damaged. If you’d like to learn more, you can read our comprehensive guide below.

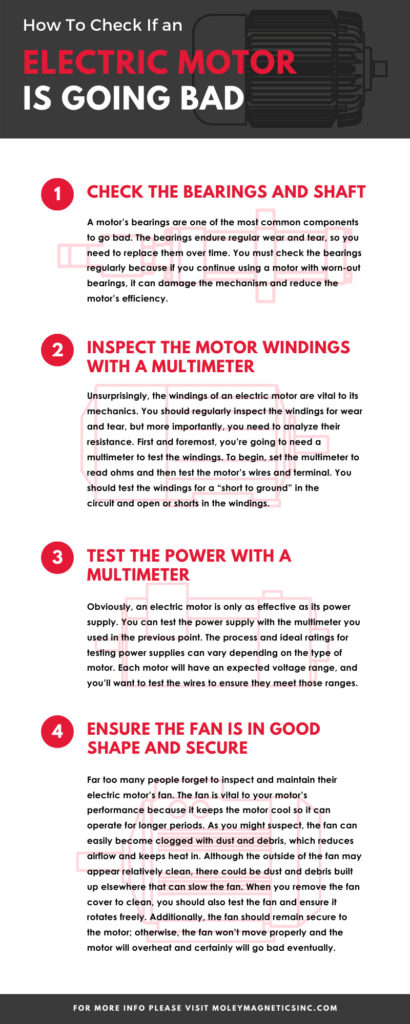

Check the Bearings and Shaft

A motor’s bearings are one of the most common components to go bad. The bearings endure regular wear and tear, so you need to replace them over time. You must check the bearings regularly because if you continue using a motor with worn-out bearings, it can damage the mechanism and reduce the motor’s efficiency.

Bearings are easy to inspect. All you’ll need to do is rotate the bearings to ensure they turn smoothly and freely. Another way to inspect the bearings is by pushing and pulling the shaft that the bearings attach to. The bearings should rotate smoothly and the shaft should be able to move smoothly as well. That said, if you hear any scraping or feel any friction, you might need to replace the bearings. If the friction is minor, the bearings might merely require lubrication.

Inspect the Motor Windings With a Multimeter

Unsurprisingly, the windings of an electric motor are vital to its mechanics. You should regularly inspect the windings for wear and tear, but more importantly, you need to analyze their resistance. First and foremost, you’re going to need a multimeter to test the windings. To begin, set the multimeter to read ohms and then test the motor’s wires and terminal. You should test the windings for a “short to ground” in the circuit and open or shorts in the windings.

To test your motor for short to ground, you’ll need to set the multimeter to ohms and disconnect the motor from its power source. Then inspect each wire and look for infinite readings. Alternatively, if you get a reading of 0, you might have a cable issue. To determine if a cable is bad, you should test each cable individually and ensure none of the leads are touching. Testing individually will allow you to find the cable causing the problem. On the other hand, if each cable is providing an infinite reading, there’s a motor problem, so you should hire a professional repair service.

To test for open or shorts in windings, you should test the T1 to T2, T2 to T3, and finally T1 to T3. Note: some motors will have different markings such as U to V, V to W, and W to U—you can find your motor’s configuration in the user manual. In general, you’re looking for a reading of .3 to 2 ohms. If you end up getting a reading of 0, you should perform the test again to see if you get 0 again. A reading of 0 means you have a shortage in phases. A shortage means the wires short to ground, which usually leads to a break in the wire. If your reading is well above 2, you likely have an open winding. An open winding simply indicates there’s a broken wire.

Test the Power With a Multimeter

Obviously, an electric motor is only as effective as its power supply. You can test the power supply with the multimeter you used in the previous point. The process and ideal ratings for testing power supplies can vary depending on the type of motor. Each motor will have an expected voltage range, and you’ll want to test the wires to ensure they meet those ranges. Your user manual will provide the necessary details for testing power along with a guide. Testing the components of an electric motor get complicated quickly, and it’s easy to make mistakes in the process if you’re not experienced.

Ensure the Fan Is in Good Shape and Secure

Far too many people forget to inspect and maintain their electric motor’s fan. The fan is vital to your motor’s performance because it keeps the motor cool so it can operate for longer periods. As you might suspect, the fan can easily become clogged with dust and debris, which reduces airflow and keeps heat in. Although the outside of the fan may appear relatively clean, there could be dust and debris built up elsewhere that can slow the fan. When you remove the fan cover to clean, you should also test the fan and ensure it rotates freely. Additionally, the fan should remain secure to the motor; otherwise, the fan won’t move properly and the motor will overheat and certainly will go bad eventually.

While some of the preventative measures we mentioned are relatively simple, you still need to know how to check if an electric motor is going bad. Some of the methods for testing a motor may require a professional’s help, and it’s crucial that you have a reliable professional to contact when you need service. That said, there are a lot of motor repair shops out there, and all of them claim to be experts, but few actually are. So how could you possibly know which company to work with? The answer is found in the company’s history, experience, and integrity.

If you’re looking for a motor servicer that’s dependable, Moley Magnetics is the company for you. Our family-owned company began as a motor repair shop, and we’re still repairing motors to this day. We take immense pride in providing top-quality service to our customers. Additionally, because we’re family-owned, we always treat our customers like they’re part of the Moley family. In other words, if you choose to work with Moley Magnetics, you’re going to receive great customer service and great products and repairs because we believe in quality. If you have any questions or you’re ready to request service, contact us today. Moreover, if your motor is beyond repair, we’ll be honest and tell you so, but don’t worry—we supply new motors too.