5 Factors That Are Weakening Your Industrial Magnetics

Magnets are incredibly useful for many industrial workers. You can lift large pieces of metal and move them from one end of a site to another, or you can separate magnetic and non-magnetic metals. However, like any other machine or tool, magnets wear out over time. In addition, various factors ranging from temperature to age can impact the way your magnet works. Find out what’s affecting yours by reading this article.

The Factors Impacting Magnets

There are various factors that are weakening your industrial magnetics. Narrowing down the cause of this issue can help you in preventing it in the future. The last thing you want is to unintentionally damage your magnet.

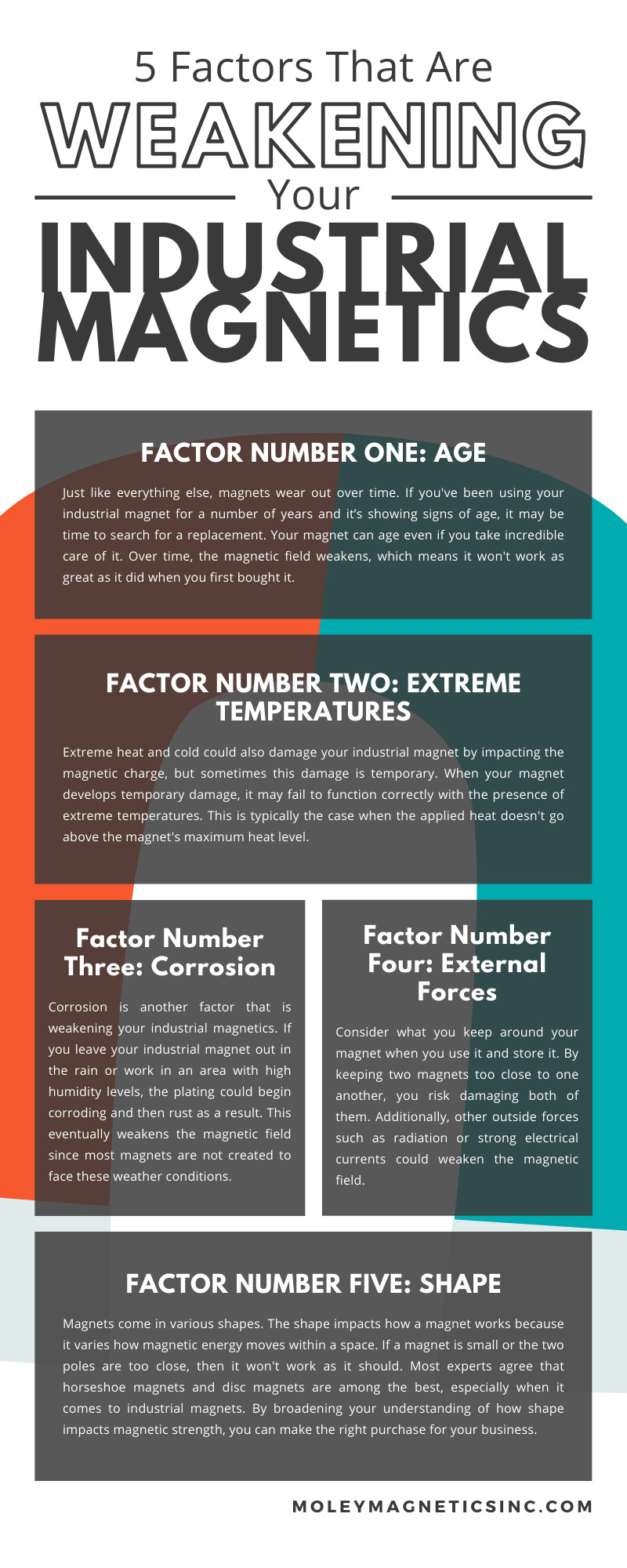

Factor Number One: Age

Just like everything else, magnets wear out over time. If you’ve been using your industrial magnet for a number of years and it’s showing signs of age, it may be time to search for a replacement. Your magnet can age even if you take incredible care of it.

Over time, the magnetic field weakens, which means it won’t work as great as it did when you first bought it.

If you notice this happening with yours, purchase a replacement as soon as possible to avoid slowing down efficiency in your workplace.

The good news is that a magnet typically takes years to demagnetize on its own. However, this is only the case when no external forces are present. Considering eliminating external factors is impossible, take good care of your magnet and get a new one when it’s worn down.

Factor Number Two: Extreme Temperatures

Extreme heat and cold could also damage your industrial magnet by impacting the magnetic charge, but sometimes this damage is temporary. When your magnet develops temporary damage, it may fail to function correctly with the presence of extreme temperatures. This is typically the case when the applied heat doesn’t go above the magnet’s maximum heat level.

Factor Number Three: Corrosion

Corrosion is another factor that is weakening your industrial magnetics. If you leave your industrial magnet out in the rain or work in an area with high humidity levels, the plating could begin corroding and then rust as a result. This eventually weakens the magnetic field since most magnets are not created to face these weather conditions.

Pro Tip

Remember to store your magnet when you’re not using it. By being proactive, you lengthen the life expectancy of your magnet and secure years of use from it.

Factor Number Four: External Forces

Consider what you keep around your magnet when you use it and store it. By keeping two magnets too close to one another, you risk damaging both of them. Additionally, other outside forces such as radiation or strong electrical currents could weaken the magnetic field.

Factor Number Five: Shape

Magnets come in various shapes. The shape impacts how a magnet works because it varies how magnetic energy moves within a space. If a magnet is small or the two poles are too close, then it won’t work as it should.

Most experts agree that horseshoe magnets and disc magnets are among the best, especially when it comes to industrial magnets. By broadening your understanding of how shape impacts magnetic strength, you can make the right purchase for your business.

Pro Tip

If you want a variety of shapes and sizes, then shop at Moley Magnetics to find the scrap yard magnet for all your heavy-duty work needs. We have been in the business for over 30 years and sell the best product as well as offer 24/7 repair. See our products on YouTube.

Industries That Use Magnets

Various job fields ranging from construction to automotive industries benefit from industrial magnets. This is because they help move heavy iron or other magnetic objects from one location to another, but magnets also help separate specific metals from non-metal things. Other fields that benefit from magnets include the following:

- Airport: Magnets help to clear the runway of scrap metal.

- Mining: Magnets make uncovering valued material simple.

- Welding: Magnets help hold metals together during bonding.

- Agriculture: Magnets can prevent food from becoming contaminated by metal.

- Mining: Magnets help separate different metal types.

Construction is another field that significantly benefits from the assistance of powerful magnets. When workers use them, they can easily lift and transport steel beams. Similarly, during the demolition process, workers may need to separate metals and non-metals on the job site, and using a magnet makes the job easy.

An Interesting Use for Magnets

Now we’ve talked about several fields that use magnets, an interesting one to include is the pharmaceutical industry. Magnets come in handy here as they remove any iron particles lying around, which helps ensure a sanitary work environment.

What To Consider Before Buying a Magnets

As you shop for the best magnet, there are various factors to evaluate, such as:

- Shape and Size: How will its shape impact its strength?

- Cost: Is it within budget?

- Operating Temperature: What are the maximizing heat and cooling temperatures?

- Usage: What will the magnet be used for, and how often?

- Material: Is it a ceramic, neodymium, or another material?

By taking these factors into account, you make it easier to find the right industrial magnet. Remember, two of these items—shape and operating temperature—directly impact how yours will work and if it will fail to function early on.

Pro Tip

As you evaluate these factors, you should also know how strong of a magnet you need. No matter what the maximum weight of your load is, it’ll always affect the magnet’s usage. By neglecting this factor, you risk purchasing a magnet with little strength, and lifting too much could lead to damage. This could also lead to an unsafe work environment since a weaker magnet could drop some of its load.

Shop at Moley Magnets

Consider Moley Magnets for all your company’s magnetic needs. As a lifting magnet supplier, we’ve got nearly everything you need to make work more efficient regardless of industry. And we don’t solely sell industrial-level magnets; we also have other essential equipment ranging from mechanical seals to the machines you need for scrap metal recycling. Purchase your high-quality magnets and equipment from an industry expert.