Excavator Safety: Everything You Need To Know

Over the years of innovation in industrial equipment, few machines have become more essential than excavators. Whether your company works in construction, railroad, scrap yards, recycling, or a mixture of industries, an excavator is essential. As the sole leader (or one of them) of the company, you’re responsible for your workers. Heavy equipment is necessary to boost a company’s productivity, efficiency, and ability to complete numerous jobs. That said, excavators can lead to serious injuries if you don’t communicate the basics of excavator safety and operation to your team. If you’re looking for a guide that discusses everything you need to know about excavator safety, we’ve got you covered. Read on to learn more.

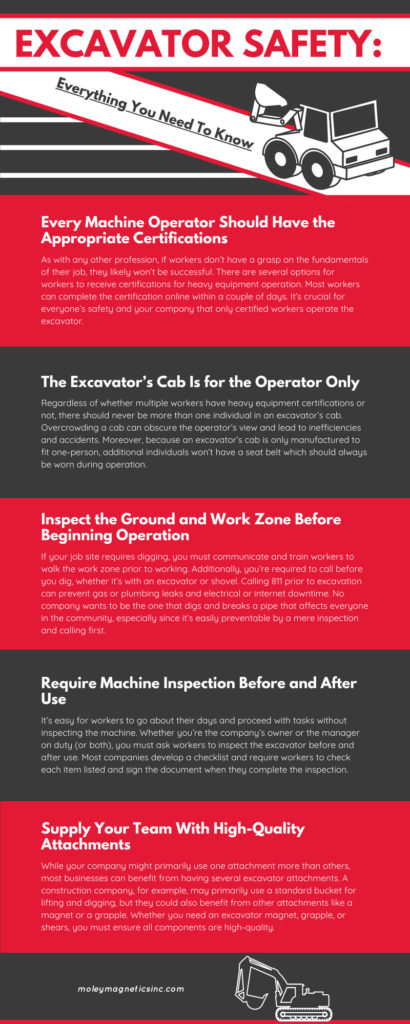

Every Machine Operator Should Have the Appropriate Certifications

As with any other profession, if workers don’t have a grasp on the fundamentals of their job, they likely won’t be successful. There are several options for workers to receive certifications for heavy equipment operation. Most workers can complete the certification online within a couple of days. It’s crucial for everyone’s safety and your company that only certified workers operate the excavator. A certified worker will understand the do’s and don’ts of excavator operation. For instance, the excavator’s arm should never be overextended unless necessary because it can make the machine unstable. Moreover, an excavator should always operate on inclines and declines slowly; an excavator should never be parallel to the ground’s slant. A certified operator would know how to dig properly and pile materials up away from the workspace, otherwise the ground could cave in. Of course, there are several other fundamentals that your machine operators need to know in order to use the excavator safely. Without proper certification and training, operators are more likely to make mistakes, potentially hurt themselves or others, or damage the machine.

The Excavator’s Cab Is for the Operator Only

Regardless of whether multiple workers have heavy equipment certifications or not, there should never be more than one individual in an excavator’s cab. Overcrowding a cab can obscure the operator’s view and lead to inefficiencies and accidents. Moreover, because an excavator’s cab is only manufactured to fit one-person, additional individuals won’t have a seat belt which should always be worn during operation. Of course, an overcrowded cab is prone to someone accidentally bumping the excavator’s controls which could lead to a much bigger problem.

Inspect the Ground and Work Zone Before Beginning Operation

If your job site requires digging, you must communicate and train workers to walk the work zone prior to working. Additionally, you’re required to call before you dig, whether it’s with an excavator or shovel. Calling 811 prior to excavation can prevent gas or plumbing leaks and electrical or internet downtime. No company wants to be the one that digs and breaks a pipe that affects everyone in the community, especially since it’s easily preventable by a mere inspection and calling first. Of course, you can use an excavator for more than digging applications. If you’re a scrapyard business, digging isn’t a primary task, but lifting and moving ferrous materials like sheet metal certainly is. Even in a scrap yard, excavator operators should make note of any barriers that might get in the way or affect the strength of their magnet. In addition to barriers, many job sites have uneven surfaces that excavators should avoid if possible.

Require Machine Inspection Before and After Use

It’s easy for workers to go about their days and proceed with tasks without inspecting the machine. Whether you’re the company’s owner or the manager on duty (or both), you must ask workers to inspect the excavator before and after use. Most companies develop a checklist and require workers to check each item listed and sign the document when they complete the inspection. There are numerous items you could include on the checklist. Some of the most important items that should be on your checklist include checking the oil, the tracks, and ensuring the attachment is secure.

While these may seem redundant, your checklist should include information like the machine’s lifting capacity to ensure the operator is aware. At the end of the day, the operator should complete the same checklist and make note of any known issues with the machine. Requiring certified workers to complete a checklist consistently holds operators accountable but also helps you make better decisions regarding machine maintenance and keeping track of oil changes, repairs, or problems. Your workers need to know that the excavator is a vital piece of equipment for the business and their career. That said, the checklist can help you manage and improve your team appropriately. If one worker consistently reports problems with the machine on their checklist but no other operator does, that first worker may be operating the machine poorly and may require additional training.

Supply Your Team With High-Quality Attachments

While your company might primarily use one attachment more than others, most businesses can benefit from having several excavator attachments. A construction company, for example, may primarily use a standard bucket for lifting and digging, but they could also benefit from other attachments like a magnet or a grapple. Whether you need an excavator magnet, grapple, or shears, you must ensure all components are high-quality. Your workers are the backbone of your company and they deserve the best equipment available. Attachments endure more wear and tear than most people realize, and low-quality attachments can fail and result in dangerous accidents. Investing in high-quality attachments upfront reduces the risk of attachments breaking down prematurely on the job, in addition to avoiding excessive repair costs.

Whether you’re a new company or you’ve been in the market for decades, safety is priority above all. Regardless of your experience, our guide includes what you need to know about excavator safety. Of course, there’s plenty more to know, so you should be familiar with your excavator’s user manual for details regarding maintenance, safety tips, and proper operation.

If you’re in the market for the best excavator attachments, look no further than Moley Magnetics. Our family-owned business consists of seasoned industry professionals with over twenty years of experience. Because we’ve been in your shoes before, we take pride in supplying exceptional products to all our customers by using only the best materials available. If you’d like to request pricing or have any questions, don’t hesitate to reach out to us. We look forward to working with you.