Will the Shape of Your Industrial Magnet Affect Its Strength?

Will the shape of your industrial magnet affect its strength? In a word, yes, but that wouldn’t be terribly instructive, would it?

As a buyer of industrial magnets, you’ve certainly noticed that all magnets are not a one-size-fits-all proposition. In the popular imagination, mostly thanks to years of watching cartoons, a magnet is always a U-shaped metal bar, usually a red one. While that may not be your experience in the real world, there’s a kernel of truth there—we’ll explain later. Perhaps most familiar to you is a short and stout cylindrical magnet, a unit that resembles a very large and very powerful hockey puck. There’s a method to that madness, too. Today, we’ll look in closer detail at how the shape of your industrial magnet will affect its strength.

Types of Lifting Magnets for the Steel Mill Industry

Among the many industrial sectors of the American economy, the steel industry is both historically and currently one of its most important. The steel industry has built America in more ways than one. Mining the iron that we process into steel provided jobs in northern Minnesota and Michigan—the famous Iron Range. The industrial heart of the Midwest is dotted with “steel towns” that grew around their mills: Gary, Indiana; Youngstown, Ohio; and Dearborn, Michigan, where the steel crossed the street to the Ford Motor Company, to name but a few. Most notable of all is the Steel City itself, Pittsburgh, Pennsylvania, the home of US Steel and the football team with a name that pays tribute to the industry.

What Is a Permanent Magnet DC Generator and How Is It Used?

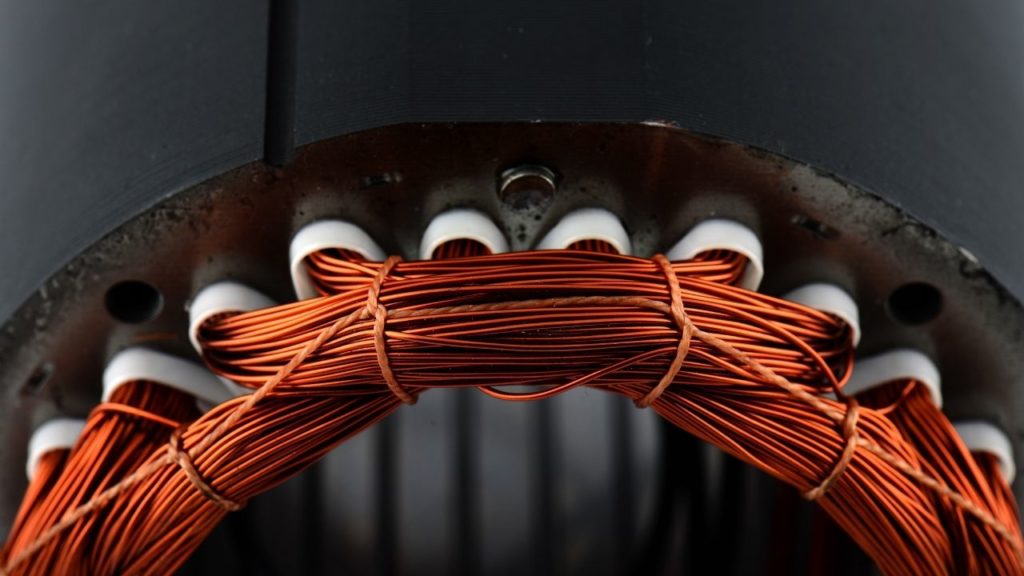

Heavy industrial work needs electromagnets. Electromagnets, of course, need electricity. Where does that electricity come from? In many cases, it doesn’t come from a three-pronged plug, a wall socket, and more than a few yards of an extension cord. Powering them isn’t like plugging in a vacuum cleaner—running this machinery in the absence of a traditional alternating current requires you to get creative. (more…)

How an Industrial Scrap Magnet Will Practically Pay for Itself

Shopping for industrial equipment can give you a nasty case of sticker shock. To be sure, nobody expects bargain-basement prices for new and necessary machinery—after all, we’re talking about the tools we use to construct and demolish buildings and infrastructure. You’re not going to get that job done with whatever’s lying around the garage. (more…)

Surprising Uses of Industrial Magnets You Probably Didn’t Know About

When you think about scrap lifting magnets in industry, there’s generally one picture that comes to mind: a big magnet on a bigger crane, swooping over a pile of scrap metal and pulling out iron and steel, moving it from one spot to another while holding the heavy scrap in place through sheer magnetic power. To be sure, you’ll see lots of magnets catching ferrous scrap if you keep an eye peeled on demolition sites and scrap yards. But electromagnets do more than sort scrap—much more. There are some surprising uses of industrial magnets you probably didn’t know about if you’ve only been concentrating on their most obvious roles in heavy industry. We’ll take a look at a few of these interesting applications below.

Reasons To Have an Industrial Scrap Magnet at Your Demolition Site

Demolition sites are busy places. You have the workers, the building set to be demolished and dismantled, and the tools, equipment, and heavy machinery the workers need to do it. As busy as these sites may be, there’s still room for one more crucial piece of equipment: an industrial scrap magnet. Eminently familiar to those in the recycling industry, this specialized heavy-duty scrap lifting magnet can also find a great deal of use on demolition jobs. There are very good reasons to have an industrial scrap magnet at your demolition site. If your arsenal of demolition equipment doesn’t yet include electromagnets, here’s why it should.

The Applications of Hydraulic Magnets

Traditional electromagnets are usually enough to do the heavy lifting at a scrap yard, construction site, or demolition site. In special cases, however, you may find that you need special equipment. A fully enclosed hydraulic magnet is a variation on the electromagnet that uses hydraulic flow to power itself without the use of an outside power source. By familiarizing yourself with the applications of hydraulic magnets, you can decide whether these devices are something you need in your arsenal.

How To Measure Magnetic Separator Strength

You’ve heard of separating the wheat from the chaff. In recycling, scrapping, and many other industries, there’s another separation goal—separating the ferrous from the non-ferrous, or the metallic from the non-metallic. Industries accomplish this with magnetic separators. Permanent and electromagnetic separators identify and set apart metallic particles that pass through, whether on conveyor belts or through pipelines. Recyclers use separators to get to the valuable copper inside granulated insulated wire. Pharmaceutical manufacturers and food processing facilities rely on separators to catch unwanted and hazardous metals that have contaminated products somewhere in the process.

How To Select Demolition Grapples

Construction is an important, rewarding, and redeeming job. But demolition—that’s where the fun comes in. It’s hard to deny the sense of satisfaction that can come from tearing down an old building, watching it come down, and clearing the space out so that construction crews can start anew on that spot. But demolition isn’t all fun and games. There’s serious work to be done when it comes to taking down construction, and the serious work calls for serious tools.