5 Essential Below-the-Hook Attachments for Overhead Cranes

The right tools make the workday easier within the industrial industry, and the same is true about attachments for this equipment. By adding five essential below-the-hook attachments for overhead cranes, you’ll make moving loads more efficient for all employees. Use this guide to deepen your knowledge on below-the-hook attachments, why you need them, and which ones most experts recommend.

What Are Below-the-Hook Attachments?

There are many types of below-the-hook devices individuals working industrial carriers utilize to lift and move heavy items. The appropriate below-the-hook device makes lifting and transporting loads more efficient. Moreover, those working at steel mills, foundries, scrap metal yards, and other similar industries often use these attachments.

Below-the-hook attachments also improve safety in the workplace because they attach to the crane to make lifting materials simple. There are slings, hooks, lifters, and more. While these are typically mechanically operated, workers can control some electronically, hydraulically, or pneumatically.

Reasons To Use These Attachments

As explained, utilizing these attachments makes the workday safer and more efficient. You can’t always use a forklift to transport heavy materials, and you can’t expect workers to move them independently. So long as workers receive the necessary training on using specialized equipment, everyone working will remain safer.

The Dos and Don’ts of Below-the-Hook Attachments

These attachments are no different than any other tools that operators will utilize. While equipment makes the workplace safer and helps workers optimize their time, this can only occur if they understand what they’re using. Likewise, employees need to know that they should never enter the swing, fall, or crush zones while another worker operates one of these machines.

The Dos

Whenever you buy a new tool, read through the owner’s manual, and have any workers operating it do the same. Also, operators must inspect the attachment to ensure it’s secure at the start of every shift. By verifying that equipment remains properly hooked up, you can prevent accidents from happening.

Noting the add-on’s weight is as important as knowing how to use the tool. By forcing the machine to overexert itself with an overly heavy attachment, you risk breaking it. This can put both materials and employees at risk.

The Don’ts

Don’t pack the owner’s manual away once you’ve read through it since you may need to refer to it soon. Instead, keep it in a labeled file to make accessing it simple. Additionally, untrained employees shouldn’t operate the device under any circumstances. Finally, never avoid recommended maintenance, as this is necessary to keep the machine functioning properly.

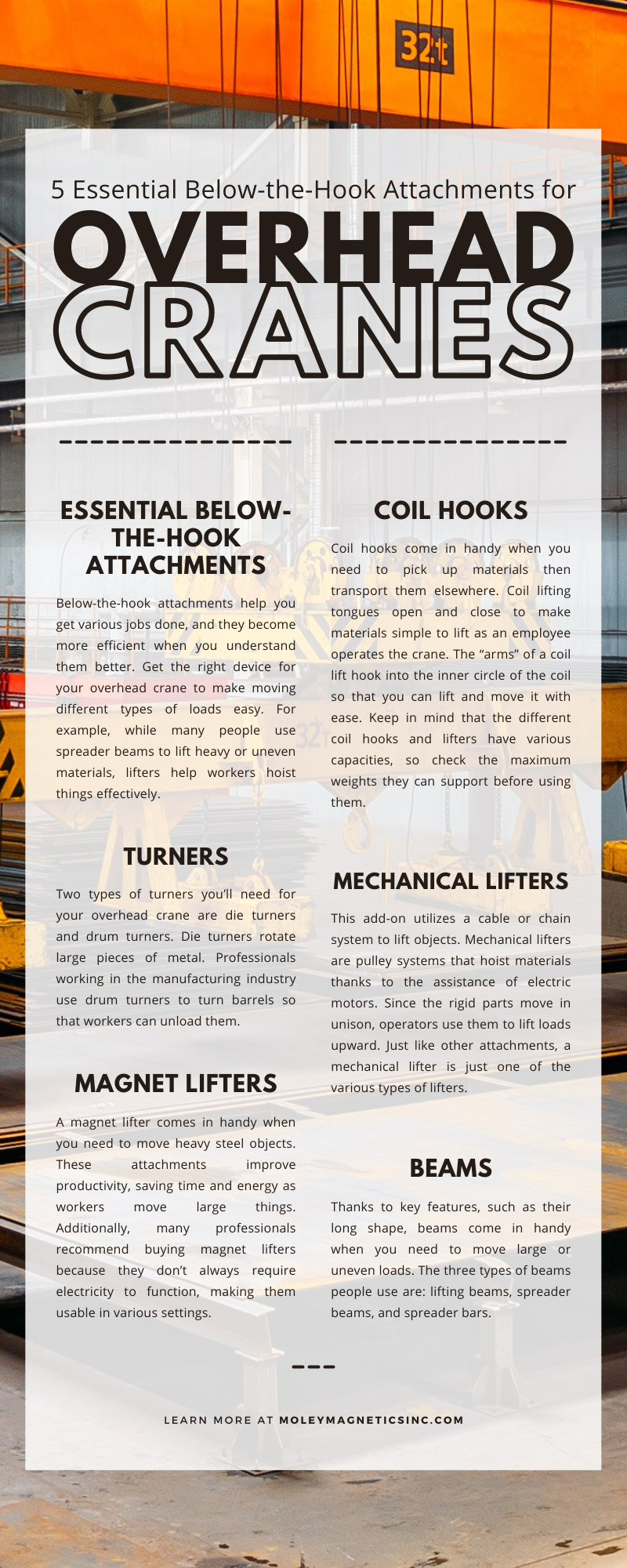

Essential Below-the-Hook Attachments

Below-the-hook attachments help you get various jobs done, and they become more efficient when you understand them better. Get the right device for your overhead crane to make moving different types of loads easy. For example, while many people use spreader beams to lift heavy or uneven materials, lifters help workers hoist things effectively.

Five essential below-the-hook attachments for overhead cranes include:

- Coil Hooks

- Turners

- Mechanical lifters

- Magnet lifters

- Beams

Adding these attachments to your work location improves daily operations by giving workers the technology they need to get a job done safely. Deepening your understanding of each tool also helps you further employee education as you purchase new assets.

Coil Hooks

Coil hooks come in handy when you need to pick up materials then transport them elsewhere. Coil lifting tongues open and close to make materials simple to lift as an employee operates the crane. The “arms” of a coil lift hook into the inner circle of the coil so that you can lift and move it with ease. Keep in mind that the different coil hooks and lifters have various capacities, so check the maximum weights they can support before using them.

Turners

Two types of turners you’ll need for your overhead crane are die turners and drum turners. Die turners rotate large pieces of metal. Professionals working in the manufacturing industry use drum turners to turn barrels so that workers can unload them.

Mechanical Lifters

This add-on utilizes a cable or chain system to lift objects. Mechanical lifters are pulley systems that hoist materials thanks to the assistance of electric motors. Since the rigid parts move in unison, operators use them to lift loads upward. Just like other attachments, a mechanical lifter is just one of the various types of lifters.

Magnet Lifters

A magnet lifter comes in handy when you need to move heavy steel objects. These attachments improve productivity, saving time and energy as workers move large things. Additionally, many professionals recommend buying magnet lifters because they don’t always require electricity to function, making them usable in various settings.

When you buy your magnet lifters from Moley Magnets, you get not only high-quality products but also one-of-a-kind customer service. Our trained technicians can come out for necessary repairs to keep your magnet lifter functioning as it should.

Beams

Thanks to key features, such as their long shape, beams come in handy when you need to move large or uneven loads. The three types of beams people use are:

- Lifting beams: These make lifting materials simple without taking up too much space.

- Spreader beams: These utilize a sling to keep their loads balanced during transport.

- Spreader bars: These use a long bar and wire rope to move heavy loads.

Remember that all three beam types give you more control as you move metals and other objects. However, each variety best serves a distinct task. For instance, spreader beams are especially useful when workers need to unload a heavy shipment with uneven weight distribution.

Where To Buy Below-the-Hook Attachments

It’s always best to buy mechanical tools and attachments from a reliable company, as this ensures quality. Purchasing from a company specialized in industrial equipment also gives you an additional resource when you need to investigate a maintenance schedule and machine safety.

Why Choose Moley Magnets?

Moley Magnets sells magnets and other necessary equipment for demolition, railroad repair, and scrap metal recycling, to name a few.

Shop at Moley Magnets for your electromagnetic crane needs. As industry experts, we have the magnetic attachments and other fabricating tools you need. And by shopping with us, you also gain 24/7 access to our repair services to confirm your equipment is always working! The right tools help your workers do their jobs successfully, and the best tools ensure their safety while they do so.